Stage Cementing Collar

Two-stage cementing is the most common of the multiple-stage cementing techniques.

We have 2 types : Mechanical Stage collar and Hydraulic stage collar

Typical Size: 7″, 9 5/8″,13 3/8″

| Size | From 4 1/2″ to 20″ |

| Origin | Shandong,China |

| Certificate | API, ISO9001 2015 |

| Loading Port | Qingdao/Tianjin China |

| Lead Time | 15-25 days |

Description

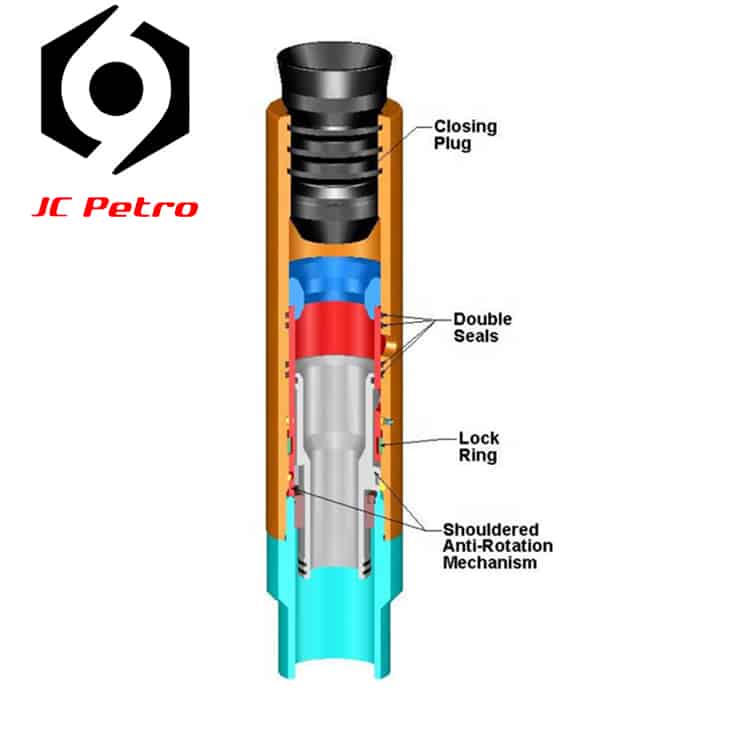

The 2 stage cementing collar provides an effective, economical way to cement one or two specific casing intervals or to cement upper zones after a lower zone has been cemented. The collar should be used with centralizers aboce and below and a cementing basket positioned below the ports. The operation of the collar is simple and reliable. It features a double locking mechanism consisting of a snap ring lock and ball lock system to assure that the ports are permanently locked closed after cementing is completed. Internal parts are designed to lock to prevent rotation during drill out and are constructed of easily drillable materials.

Two stage cementing is the most common of the multiple-stage cementing techniques.Multi stage cementing tools allow for selected intervals around the casing string to be cemented at separate times or in stages. New technologies and techniques have led to the use of lightweight cement solutions in some situations that would conventionally call for multi stage cementing collar.

We are cementing collar manufactturer and supplier with API 5CT. Hydraulic & Mechanical Stage Cementing Collar can be offered.

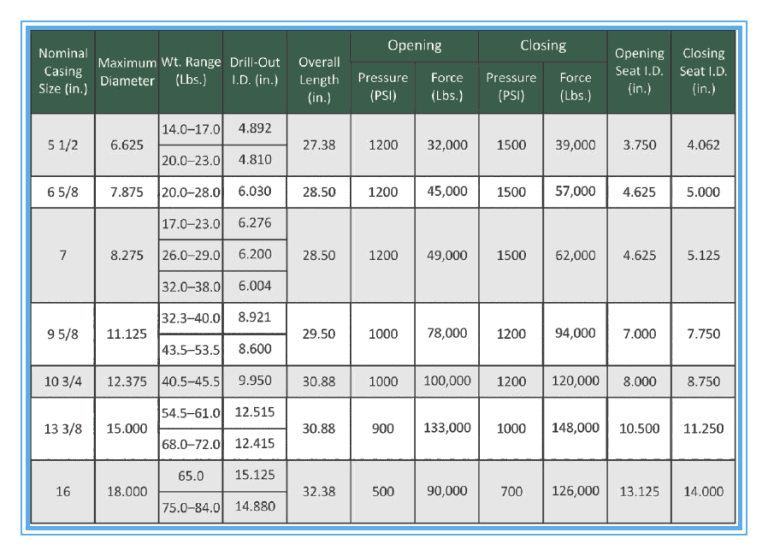

Mechanical Stage Collar

Mechanical Stage collar ( Mechanical stage cementing tool) allows cementing of casing string in two stages. These collar set the standard for reliability, cost effectiveness, and ease of use with outstanding built-in features and quality. They are the collars of choice when drilling requirements call for proven technology and low risk. The compact, simple design minimizes the number of moving parts and makes the tools easier to handle.

The collar’s clear opening and closing indications at the surface accommodate the hydraulic conditions of the well for safer, more efficient operations. The internal sleeves increase reliability and prevent premature opening from formation restrictions on applied pressures.

It reduces total pumping pressure in long casing strings.

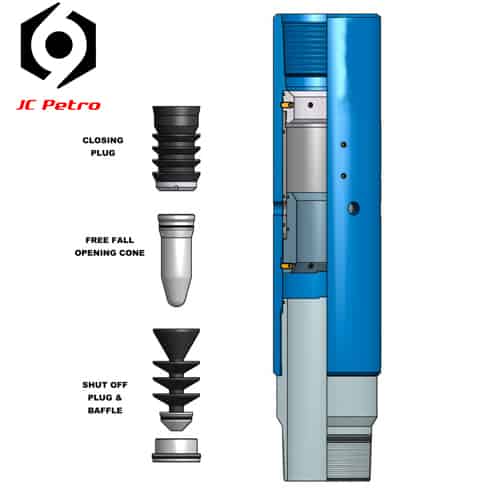

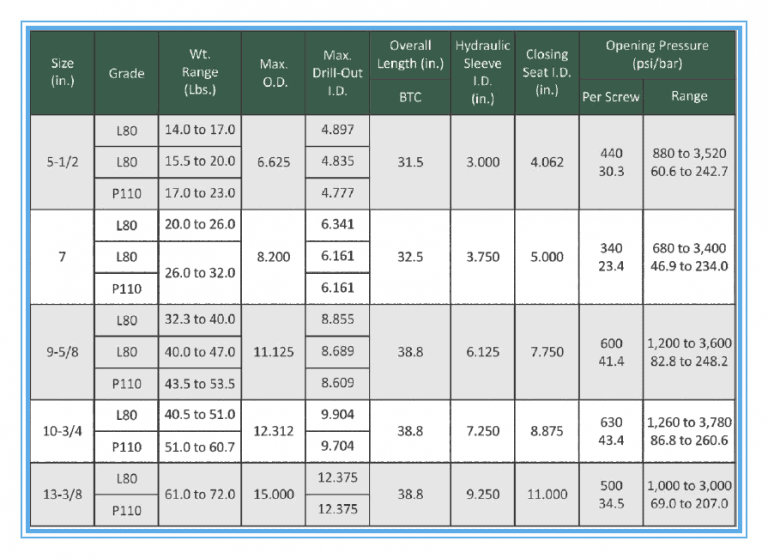

Hydraulic Stage Collar

Hydraulic stage collar (hydraulic stage cementing tool) meets the challenges of cementing holes at any angle with a hydraulically opened port system. Stage collar designed specifically for horizontal completion.It is specifically used for Primary cementing in deep vertical or high deviated horizontal-well conditions.

It reduces total hydrostatic pressureon weak formations to prevent lost circulation during cementing.

Clear surface indications of opening and closing pressures provide safer and more efficient operations.

The opening pressure of the stage collar can be adjusted at rig site to meet well requirements, providing operational flexibility.

Drilling stage cementing tool is a special equipment which divided the cementing job for twice.It’s mainly used for the following condition.

Application

stage cementing tool is a special equipment which divided the cementing job for twice.

1. Hydraulic stage collar meets the challenges of cementing holes at any angle with a hydraulically opened port system.

2. Stage collar designed specifically for horizontal completion.

3. It is specifically used for Primary cementing in deep vertical or high deviated horizontal-well conditions.

4.It reduces total hydrostatic pressureon weak formations to prevent lost circulation during cementing.

5.Clear surface indications of opening and closing pressures provide safer and more efficient operations.

6.The opening pressure of the stage collar can be adjusted at rig site to meet well requirements, providing operational flexibility.

What is the size of Cement Head you can manufacture?

From 4 1/2″ to 20″.

How to work

The operation of the collar is simple and reliable. It features a double locking mechanism consisting of a snap lock and ball lock system to assure that the ports are permanently locked closed after cementing is completed. Internal parts are designed to lock to prevent rotation during drill out and are constructed of easily drillable materials.

The Multiple Stage Cementing Collar provides a means of opening and closing port holes for cement displacement and positive containment of the cement after displacement. All internal parts are drillable, and are held from rotating during drilling.

The port closing sleeve is positively locked in position after cementing.

When running the Collar, it is advisable to place Casing Centralizers above and below the tool, and to run a Cementing Basket below the cementing ports.

After running the Collar to setting depth, the lower section is cemented in the conventional manner, except the cement is displaced with the flexible cementing plug furnished with the collar. This is bumped against the shut-off Baffle which is also included.

A slight pressure build-up of 300-400 PSI will help to seat the plug in the Baffle. The port holes in the Multiple Stage Cementing Collar are opened for the second stage by dropping the trip bomb and applying approximately 800-1000 PSI pressure . The second stage is displaced with the closing plug, which is also furnished with the Tool. When the closing plug bumps approximately 800-1000 PSI, the pressure will close the port holes.